Get in touch: +1-215-785-2400 8am - 5pm EDT

Email us: info@btecsolutions.com

What is Additive Manufacturing?

There are in fact a number of different subtypes of additive manufacturing including 3D printing, but also rapid prototyping and direct digital manufacturing (DDM). Recent advances in this technology have seen its use become far more widespread and it offers exciting possibilities for future development.

How Does it Work & What is Involved?

The clue to the basics of additive manufacturing; rather than producing an end result by taking material away, it adds to it instead.

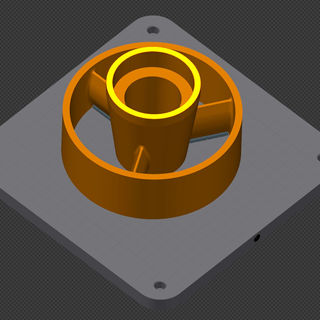

Traditional manufacturing methods involve a material being carved or shaped into the desired product by parts of it being removed in a variety of ways. Additive manufacturing is the polar opposite, structures are made by the addition of thousands of minuscule layers which combine to create the product. The process involves the use of a computer and special CAD software which can relay messages to the printer so it “prints” in the desired shape.

Suitable for use with a range of different materials, the cartridge is loaded with the relevant substance and this is “printed” into the shape, one wafer-thin layer at a time. These layers are repeatedly printed on top of each other, being fused together during the process until the shape is complete.

The Benefits

Conventional manufacturing techniques are capable of producing a great range of shapes and designs but additive manufacturing takes production to the next level.

One of the greatest benefits of this more modern technology is the greater range of shapes which can be produced. Designs that can’t be manufactured in one entire piece with traditional means can easily be achieved. For example, shapes with a scooped out or hollow center can be produced as a single piece, without the need to weld or attach individual components together. This has the advantage of being stronger; no weak spots which can be compromised or stressed.

The additive manufacturing process is very quick too, rather than needing an endless round of meetings from engineers in order to be able to tweak designs. With the assistance of the CAD software, making any changes takes simply the click of the mouse. Rapid prototyping in particular is very quick, with full models produced quite literally overnight in some cases. This provides companies with far more flexibility, and also has the result of slashing costs too.

In the past, the limitations of production have all too often influenced design, ruling out ideas because they weren’t practically achievable. The introduction of this technology and its development means the process has been spun on its head, with design now driving the production.